Part manufacturing also in contract manufacturing

The conscientious manufacture of parts is an important preliminary step for every production — because in this work step, too, the decisive course is set for a satisfactory later function.

In order to guarantee this to us and our customers in the best possible way, we manufacture all parts directly in-house. This gives us the project security that we and our company stand for. We also offer you the option of having the parts you need produced by us — regardless of whether you purchase additional services or products from us.

our services for you

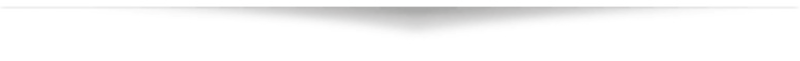

CNC turning

8 CNC lathes and additional conventional lathes are available for turning.

Steels, stainless steels, aluminum, non-ferrous metals are processed.

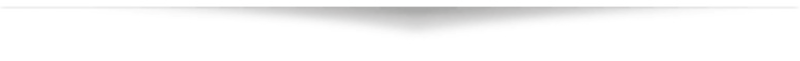

CNC milling

CNC milling machines and additional conventional milling machines are available for milling.

Steels, stainless steels, aluminum, non-ferrous metals are processed.

CNC grinding

Grinding on a workpiece usually takes place as one of the last machining operations.

This processing brings the finishing touch and enables the required surface quality, as well as the geometric accuracy. Here we ensure the highest repeatability on our CNC cylindrical grinding machines for grinding results up to 5 µm tolerance.

Prototype construction

Our team from the Prototype Construction division plans and develops new technical products — from the idea to functional prototypes to series production. We see ourselves as an “external” process accelerator in product development with core competencies in pre-development.

Large and small series

Anyone who wants to lead a product idea to series production in the foreseeable future is in a conflicting situation: on the one hand, the design must be implemented as soon as possible in order to demonstrate market presence, on the other hand, premature decisions in the toolmaking sector can sometimes increase project costs and runtimes. This is exactly where we start and offer tailor-made solutions — for both large and small series.

Quality Assurance

Our quick release systems combined with the offer for customer-specific design and manufacture require efficient in-house quality assurance.

In this way, we offer our customers a continuous process chain from design to production and quality assurance.

Laser marking

Laser marking and marking is suitable for almost all materials and shapes for marking, marking and engraving.

Steel, stainless steel, aluminum and non-ferrous metals are labeled.

Pouch packaging

Thanks to our bag packaging machine, we offer ziplock bags in individual sizes.

So we always deliver your products perfectly labeled and packaged.